Our story is a story about family, tradition, knowledge and priceless experience that are woven into a perfect product - LAMAR parquet. Although Samatini d.o.o. as a company was officially established in 2007, its founding was simply the culmination of decades of experience in production of products made from wood, parquets and flooring. Tradition, quality and inovation are the foundation of the values on which we created our brand - LAMAR parquet.

The main activity of our company is the production of the original three-layer and two-layer parquet LAMAR. While initially focusing on the creation of the lower two layers (so-called parquet carpet) for some of the world's best-known manufacturers of wooden floors (TILO and PARADOR from Austria, PARKETT HERTER from Germany, GALIMBERTI from Italy, etc.), through continuous investments, technological development and education Samatini soon began with the production of the top layer, enabling us to create our recognizable brand - LAMAR parquet - whose quality and longevity have been proven through excellent customer reception and significant market share in the southeast, as well as in Western Europe, and more and more around the world.

Exponential growth in demand required continuous expansion of the production, which is why Samatini today has the capacity to produce 30.000 m2 of parquet and 50.000 m2 the so-called parquet carpet every month. With state-of-the-art technologies implemented in the production lines, Samatini is able to create LAMAR parquets up to 5.5 m in length and up to 56 cm wide, designed for joining by tongue & groove system, which simplifies the installation and provides an additional level of stability to the installed floors. We conduct almost all of the production in-house, from processing of the logs to the production of parquet, all done on high quality machinery that enables a very high precision of the manufacturing.

The quality and durability of wooden floors depends largely on the dryness of the wood from which they are made, which is why we make LAMAR parquet exclusively from wood that is gradually dehydrated to the optimum humidity in our modern wood dryers. This process guarantees parquet's longevity and durability in any application.

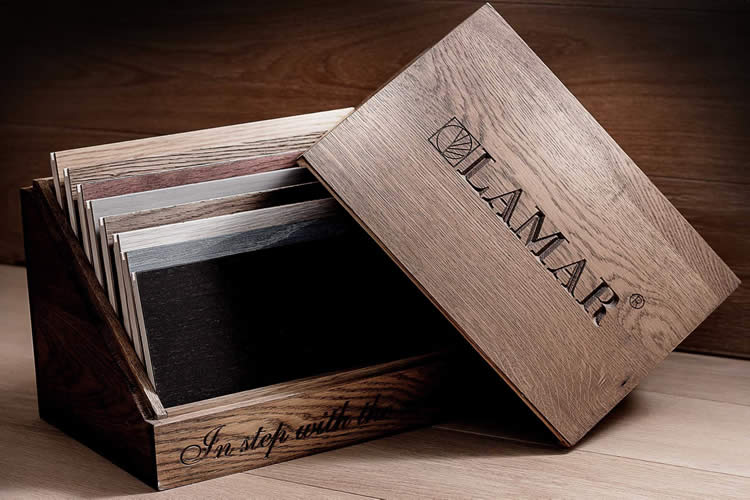

Well-known oak, unique steamed beech, thermotreated ash are just some of the raw materials we use in the production of parquet. By carefully selecting the wood structure used in production, we create the most aesthetically pleasing floor you will ever see, giving each room its most dominant feature. The character of the master-crafted LAMAR parquet is stylized by its surface finishing, from natural (classic), through hand-brushed or scraped to innovative distressed retro look. Fully stylized parquet is completed with a perfect coating of natural high-quality oils or varnishes, available in many different colors and shades to suit every decoration and taste, allowing the natural look of the wood to stand out, while at the same time being resistant to regular use and maintenance. The possibilities are practically infinite when it comes to the desired look of LAMAR parquet which customers can get.

Samatini prides itself with a status of an ecologically conscious factory. LAMAR parquet is made from 100% natural wood, using only ecological glues, oils and lacquers. Production facilities are regularly upgraded to eliminate harmful emissions into the environment and to recycle residues from the production.

Samatini LAMAR wants to provide its clients with the highest standards of quality in relation to the materials and parquet manufacturing, as well as regulations and the environment. For this reason Samatini d.o.o. possesses credible certificates of independent institutions, which guarantee high quality of the production and uniqueness of our product.

Certification of wood quality ( Euroinspekt-drvokontrola d.o.o.) HRN EN ISO/IEC 17025

CE sign – Confirmation that our products fullfil security requirements prescribed by the EU directives on materials used in production.